Screwed End Gate Valve

Screwed End Gate Valve Specification

- Structure

- Gate Type

- Connection

- Screwed (Threaded)

- Size

- 1/2 to 4

- Sealing

- PTFE / Soft Seated

- Material

- Forged Brass / Stainless Steel

- Type

- Screwed End Gate Valve

- Power Source

- Manual

- Pressure

- PN16

- Media

- Water, Oil, Gas

- Working Temperature

- -10C to 80C

- Port Size

- 15 mm to 100 mm

- Surface

- Polished

- Shape

- Straight

- Operator

- Handwheel

- Packing Type

- Carton Box / Wooden Case

- End Connections

- BSP / NPT Threaded

- Flow Direction

- Bi-directional

- Testing Pressure

- 1.5 times working pressure

- Stem Type

- Non-rising / Rising

- Body Finish

- Nickel Plated / Natural Finish

- Application

- Industrial, Domestic, Plumbing

- Leakage Rate

- Zero Leakage

- Mounting Position

- Vertical / Horizontal

- Handle Material

- Cast Iron / Steel

Screwed End Gate Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About Screwed End Gate Valve

Backed by a team of diligent working experts, we are engrossed in supplying the best in class Screwed End Gate Valve that is popularly known among our customers owing to its superior design, high build quality, and steadfast construction. The gate valve does not degrade in quality or become inferior in the long run due to chemical attacks, rust, and shear forces. It is available in varied technical configurations and types. Screwed End Gate Valve is easy to install and maintain. Our customers can get the product delivered to their door-step within the stipulated time frame.

Main Features :

- Bolted body-bonnet design for valves up to Class 800, 1500, 2500, 4500. Valves with welded bonnet also available on request

- Screwed with a seal-welded body-bonnet design for valves of Class 1500,2500, 4500.

- Bellows-sealed Gate and Globe valves available in Class 800

- Bolted body-bonnet joints provided with spiral-wound stainless steel gasket and graphite filler for maximum protection against leaks

- Die-formed graphite inner packing rings and braided graphite end rings with Inconel wire reinforcement and corrosion inhibitor

- T-head stem-disc connection of gate valve fully meets strength requirements of API 602 and API 598

- Rolled ACME thread on stem for smooth operation

- Tapered shoulder on the stem for back seating

- Self-aligning type gland assembly with stud-and-nut tightening

- Integral hard-faced body seat for globe and check valves

- Spring-loaded disc on check valves suitable for no horizontal applications too

- Gate and globe valves can be offered with electrical actuators

- Austenitic SS forging for body and bonnet of Cryogenic valves, resulting in excellent impact strength, minimal heat loss and resistance to corrosion

- Valves can be offered to NACE MR-0175 and other special NACE requirements

Flexible Mounting and Application

Designed for versatility, this gate valve supports both vertical and horizontal mounting positions. Its straight shape and polished surface provide an elegant and durable solution for industrial, domestic, and plumbing systems. With bi-directional flow, it seamlessly manages water, oil, and gas media in various setups.

Superior Performance and Reliability

Engineered with forged brass or stainless steel, the valve ensures robust operation under tough conditions. The PTFE or soft-seated seals guarantee zero leakage, while a rigorous testing process at 1.5 times the working pressure maintains performance standards and reliability across all supplied valves.

Wide Size Range and Simple Installation

Available from 1/2" to 4" (15 mm to 100 mm), the valve connects via BSP or NPT threaded ends, making it ideal for quick installation in diverse networks. Each unit comes packed in a carton box or wooden case for safe transport and delivery by distributors, exporters, manufacturers, and suppliers in India.

FAQ's of Screwed End Gate Valve:

Q: How is the Screwed End Gate Valve installed in a pipeline?

A: The valve is installed using BSP or NPT threaded connections, allowing direct screwing into compatible pipework. It can be mounted in either vertical or horizontal positions, providing flexibility in various plumbing or industrial setups.Q: What types of media can the valve handle?

A: This valve supports water, oil, and gas, making it suitable for use in domestic plumbing, industrial processes, and oil transportation systems. Its bi-directional flow capability ensures reliable control in any direction.Q: When should a non-rising or rising stem type be selected for the gate valve?

A: Non-rising stems are often preferred in spaces with limited vertical clearance, while rising stems offer visible position indication. Selection depends on installation space and monitoring requirements.Q: Where can this gate valve be applied?

A: It is ideal for industrial plants, residential water systems, and commercial plumbing installations thanks to its robust construction and zero leakage sealing. As a versatile product, distributors, suppliers, and traders in India provide it for many applications.Q: What is the benefit of the valve's zero leakage rate and soft-seated PTFE sealing?

A: Zero leakage ensures reliable shutoff and prevents wastage or safety risks. PTFE or soft-seated seals deliver excellent chemical resistance and enhance the valve's sealing capabilities for long-term performance.Q: How is the valve tested for reliability?

A: Each valve undergoes pressure testing at 1.5 times its working pressure. This ensures structural integrity and reliable operation under normal and challenging conditions.Q: What is the recommended process for handling and packaging the valve during shipping?

A: Valves are packed in sturdy carton boxes or wooden cases to ensure safe transit, preventing damage and maintaining product quality for distributors and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valves By End Connection Category

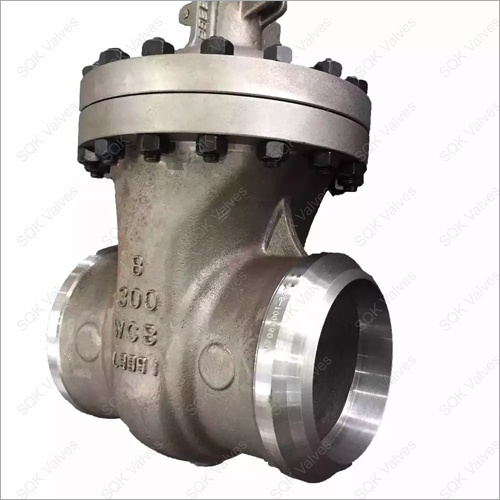

Socket Weld Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Port Size : 1/2 inch to 2 inch

Working Temperature : Other, 20C to 250C

Material : Other , Forged Steel / Stainless Steel

Surface : Polished

Buttweld End Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Port Size : Standard (Customizable)

Working Temperature : Other, 20C to 200C

Material : Other , Carbon Steel / Stainless Steel

Surface : AntiCorrosive Coated

Flange End Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Port Size : 2 inch to 24 inch

Working Temperature : Other, 10C to 80C

Material : Other , Cast Iron / Ductile Iron / Carbon Steel

Surface : Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese