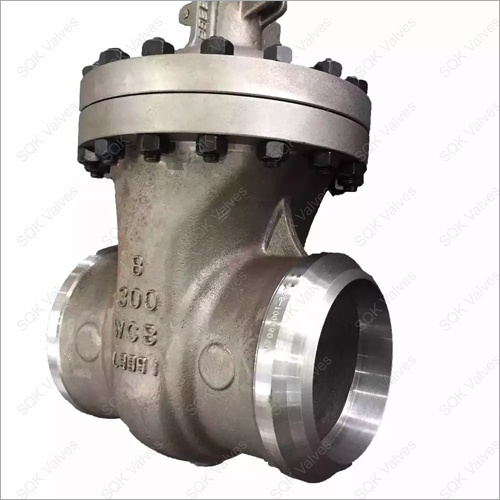

Flange End Gate Valve

Flange End Gate Valve Specification

- Sealing

- Metal to Metal / Resilient Seated

- Connection

- Flanged Ends as per DIN/ANSI/BS

- Size

- Range available from 50mm to 600mm

- Structure

- Gate

- Material

- Cast Iron / Ductile Iron / Carbon Steel

- Type

- Flange End Gate Valve

- Power Source

- Manual

- Pressure

- PN10, PN16, PN25

- Media

- Water, Oil, Gas, Steam

- Working Temperature

- -10C to 80C

- Port Size

- 2 inch to 24 inch

- Surface

- Coated

- Shape

- Round

- Gland Packing

- Graphite/ PTFE

- Stem Material

- Stainless Steel / Carbon Steel

- End Connection Standard

- ANSI B16.5, BS 4504, DIN 2501

- Testing Standard

- ISI / API 598

- Operating Torque

- Standard, manual handwheel driven

- Number of Holes in Flange

- As per flange standard

- Face to Face Standard

- As per DIN/ ANSI/ BS

- Body Material Standard

- IS 14846, BS 5163, DIN, ANSI

- Working Medium

- Water, Gas, Oil, Steam

- Coating

- Epoxy or Enamel Painted

- Application

- Water Supply, Wastewater, Industrial Pipelines

- Handwheel Material

- Cast Iron

- Bonnet Type

- Bolted Bonnet

Flange End Gate Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About Flange End Gate Valve

Flange End Gate Valve that we are offering is widely acclaimed among our customers owing to its ruggedness and longevity. The gate valve is a mechanical tool designed for the processing of fluids and liquid chemicals. It can regulate the flow, control the pressure of the flow of liquids, and distribute liquids precisely. The gate valve has got rugged construction and capability of enduring impacts, rust, and shear forces, therefore, it does not degrade in quality or become inferior in the long run. Our customers can approach us to purchase the Flange End Gate Valve at a cost-effective price.

The API 600 Gate Valves is exceptionally sturdy, rugged, and durable, with a reputation for quality, integrity, and long service.

They are designed for tight sealing and ease of operation. The valves are available flanged & butt-weld ends in pressure rating from ASME Class 150 to Class 2500, and in a variety of materials of construction.

Gate Valves are of flexible wedge design, outside screw and yoke, and bolted-bonnet construction. The valves conform to API 600.

Main features :

- Bolted body-bonnet design, seal welded & Valves with pressure seal bonnet

- Bellows-sealed Gate and Globe valves available

- Bolted body-bonnet joints provided with spiral-wound stainless steel gasket and graphite

- filler for maximum protection against leaks

- Die-formed graphite inner packing rings and braided graphite end rings with Inconel wire

- reinforcement and corrosion inhibitor

- T-head stem-disc connection of gate valve fully meets strength requirements of API 602 and API 598

- Rolled ACME thread on stem for smooth operation

- Tapered shoulder on the stem for back seating

- Self-aligning type gland assembly with stud-and-nut tightening

- Integral hard-faced body seat for globe and check valves

- Spring-loaded disc on check valves suitable for no horizontal applications too

- Gate and globe valves can be offered with electrical actuators

- Austenitic SS forging for body and bonnet of Cryogenic valves, resulting in excellent impact strength, minimal heat loss and resistance to corrosion

- Valves can be offered to NACE MR-0175 and other special NACE requirements

Versatile Connectivity and Sealing

This valve offers versatile end connection compliance with ANSI B16.5, BS 4504, and DIN 2501 standards, ensuring seamless integration into multiple pipeline systems. Users can choose from metal-to-metal or resilient seated sealing, optimizing reliability and longevity in diverse operating environments.

Robust Design Tailored for Industrial Use

Built with a bolted bonnet structure, the gate valve guarantees leak-tight performance under varying pressures. Gland packings are made from graphite or PTFE for enhanced sealing, and the valve is suitable for both standard and resilient-seated applications, tackling a wide range of fluids including water, oil, gas, and steam.

FAQ's of Flange End Gate Valve:

Q: How is the Flange End Gate Valve operated and maintained?

A: This valve is manually operated via a cast iron handwheel, offering straightforward, reliable actuation. Regular maintenance involves checking the stem (stainless or carbon steel), gland packing (graphite/PTFE), and surface coating to ensure optimal performance and longevity.Q: What industries and applications are suitable for this gate valve?

A: The valve is ideal for water supply, wastewater management, and industrial pipelines. Its resilience and design also make it suitable for transporting oil, gas, and steam, across municipal, utility, and manufacturing sectors.Q: When should I select a metal-to-metal versus a resilient seated gate valve?

A: Choose metal-to-metal sealing for higher temperatures or abrasive media, while resilient seated options cater to applications demanding tight shut-off and reduced leakage, typically used with water or non-abrasive liquids.Q: Where can these valves be installed in a piping system?

A: Thanks to compliant flange standards (ANSI, DIN, BS), these valves can be readily installed wherever flange-end connections are present, from mains in water treatment plants to distribution lines in industrial facilities.Q: What is the process for testing the valve's quality and integrity?

A: Each valve undergoes rigorous pressure and leak testing in accordance with ISI and API 598 standards. This ensures the valve's reliable operation and compliance with strict industry requirements.Q: How does the epoxy or enamel coating benefit the valve?

A: The protective surface coating shields the valve from corrosion and environmental wear, extending service life even in demanding or corrosive atmospheres such as wastewater and petrochemical applications.Q: What are the benefits of using a bolted bonnet structure in this valve?

A: A bolted bonnet design provides superior sealing at the body-bonnet joint, facilitates easier maintenance and inspection, and reinforces structural integrity under high-pressure conditions, ensuring safe and leak-free operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valves By End Connection Category

Buttweld End Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Shape : Straight

Connection : Other, Buttweld End

Surface : AntiCorrosive Coated

Media : Other, Water, Oil, Gas, Steam

Screwed End Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Shape : Straight

Connection : Other, Screwed (Threaded)

Surface : Polished

Media : Other, Water, Oil, Gas

Socket Weld Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Shape : Straight

Connection : Other, Socket Weld

Surface : Polished

Media : Other, Water, Oil, Gas, Steam

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese