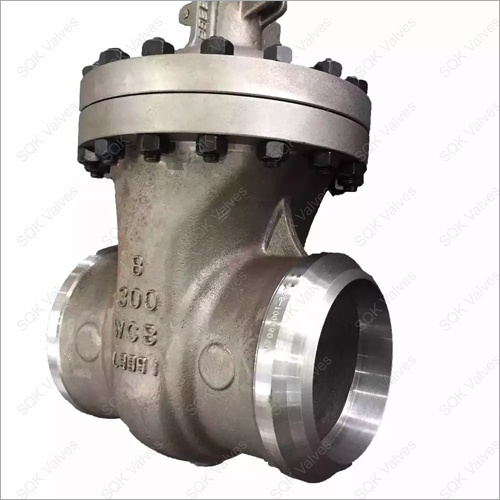

Buttweld End Gate Valve

Buttweld End Gate Valve Specification

- Sealing

- Metal-to-Metal, Soft Seated

- Size

- 1/2 to 24

- Connection

- Buttweld End

- Structure

- Rising / Non-Rising Stem

- Material

- Carbon Steel / Stainless Steel

- Type

- Gate Valve

- Power Source

- Manual

- Pressure

- Up to 40 Bar

- Media

- Water, Oil, Gas, Steam

- Working Temperature

- -20C to 200C

- Port Size

- Standard (Customizable)

- Surface

- Anti-Corrosive Coated

- Shape

- Straight

- Stem Type

- Forged Steel / Stainless Steel

- Body Material Options

- WCB, CF8, CF8M, Alloy Steels

- End Finish

- Beveled Ends Suitable for Welding

- Application

- Petrochemical, Power Plants, Refineries, Water Supply

- Seat Material

- Metal Alloy / PTFE

- Coating Type

- Epoxy / PU

- Face to Face Dimension

- ANSI B16.10

- Maintenance

- Low

- Product Certification

- ISO 9001:2015

- Design Standard

- API 600 / ASME B16.34

- Testing Standard

- API 598

- Handwheel Operation

- Yes

- Leakage Class

- Class VI

- Flow Direction

- Bi-Directional

- Bonnet Type

- Bolted Bonnet

Buttweld End Gate Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About Buttweld End Gate Valve

Buttweld End Gate Valves

Buttweld End Gate Valves are accessible with good functionality. These are made from high-quality forged steel and are specially developed for manufacturing applications. The said valves are highly suitable for their effective use in non-corrosive media such as steam, gas, water, or oil etc. Buttweld End Gate Valves have a functional design. These are needed for ensuring high functionality. These allow for reliable sealing and have accessibility in various configuration. The provided valves have a barrier which are needed to stop the sealing material from sneaking.

The API 600 Gate Valves is exceptionally sturdy, rugged, and durable, with a reputation for quality, integrity, and long service.

They are designed for tight sealing and ease of operation. The valves are available flanged & butt-weld ends in pressure rating from ASME Class 150 to Class 2500, and in a variety of materials of construction.

Gate Valves are of flexible wedge design, outside screw and yoke, and bolted-bonnet construction. The valves conform to API 600.

Main features :

- Bolted body-bonnet design, seal welded & Valves with pressure seal bonnet

- Bellows-sealed Gate and Globe valves available

- Bolted body-bonnet joints provided with spiral-wound stainless steel gasket and graphite

- filler for maximum protection against leaks

- Die-formed graphite inner packing rings and braided graphite end rings with Inconel wire reinforcement and corrosion inhibitor

- T-head stem-disc connection of gate valve fully meets strength requirements of API 602 and API 598

- Rolled ACME thread on stem for smooth operation

- Tapered shoulder on the stem for back seating

- Self-aligning type gland assembly with stud-and-nut tightening

- Integral hard-faced body seat for globe and check valves

- Spring-loaded disc on check valves suitable for no horizontal applications too

- Gate and globe valves can be offered with electrical actuators

- Austenitic SS forging for body and bonnet of Cryogenic valves, resulting in excellent impact strength, minimal heat loss and resistance to corrosion

- Valves can be offered to NACE MR-0175 and other special NACE requirements

Robust Construction & Versatile Applications

Made from WCB, CF8, CF8M, and various alloys, this gate valve excels in demanding environments, handling media like water, oil, gas, and steam. The bolted bonnet, beveled buttweld ends, and epoxy/PU coating enhance durability and longevity across petrochemical, refinery, power plant, and water supply installations.

Superior Sealing & Reliable Performance

Equipped with metal alloy or PTFE soft seats, and forged steel or stainless steel stems, the valve offers metal-to-metal and soft sealing options. Its leakage class VI rating ensures the highest possible sealing integrity, while the bi-directional flow capability supports flexible system layouts.

Certified Quality & Customizable Design

Complying with ISO 9001:2015 and global standards (API 600, ASME B16.34, ANSI B16.10, API 598), the gate valve guarantees rigorous quality and performance. Customizable port sizes and surface finish options are available to meet specific site requirements, ensuring optimal function and compatibility.

FAQ's of Buttweld End Gate Valve:

Q: How is the Buttweld End Gate Valve installed in industrial systems?

A: The valve comes with beveled ends specifically designed for welding into pipelines, ensuring a secure, leak-proof connection suitable for petrochemical, power generation, refinery, and water supply applications.Q: What materials are available for the body and seat components of this gate valve?

A: Body options include WCB (carbon steel), CF8 (stainless steel), CF8M, and alloy steels. Seat materials are available in durable metal alloys or PTFE for enhanced corrosion resistance and flexibility in aggressive or mild media.Q: When should I choose a rising stem or a non-rising stem structure?

A: Rising stem valves provide visible stem movement for open/close indication, ideal in settings where position monitoring is crucial. Non-rising stem designs suit areas with limited space, offering compact operation while maintaining robust sealing.Q: Where can the Buttweld End Gate Valve be used?

A: It is suitable for deployment in petrochemical plants, power stations, refineries, and water supply networks-anywhere reliable shut-off for water, oil, gas, or steam is needed at pressures up to 40 Bar and temperatures from -20C to 200C.Q: What is the process for valve testing and certification?

A: Each valve is rigorously tested per API 598 for leakage and operational integrity and certified under ISO 9001:2015, ensuring it meets industry benchmarks for safety and performance before shipment.Q: How does manual handwheel operation benefit system maintenance?

A: Handwheel operation offers straightforward manual control, simplifying valve adjustment and reducing the need for complex actuation systems. The design promotes low ongoing maintenance, minimizing downtime and operational costs.Q: What are the advantages of the anti-corrosive coating on the valve's surface?

A: Epoxy or polyurethane coatings protect the valve from external corrosion, extending service life in harsh environments and maintaining reliable performance across varied applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valves By End Connection Category

Screwed End Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Port Size : 15 mm to 100 mm

Structure : Other, Gate Type

Pressure : Other, PN16

Connection : Other, Screwed (Threaded)

Flange End Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Port Size : 2 inch to 24 inch

Structure : Gate

Pressure : Other, PN10, PN16, PN25

Connection : Other, Flanged Ends as per DIN/ANSI/BS

Socket Weld Gate Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Port Size : 1/2 inch to 2 inch

Structure : Gate

Pressure : Other, Class 150 to Class 800

Connection : Other, Socket Weld

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese