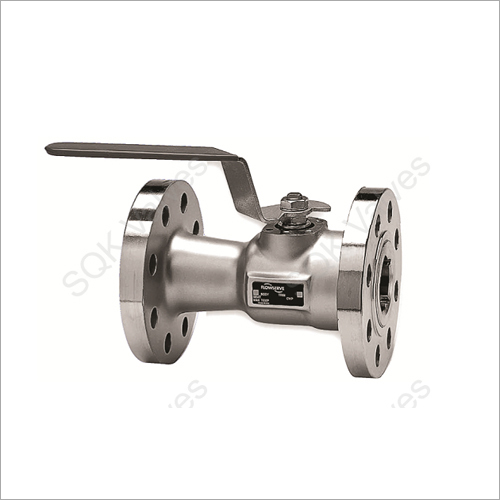

Side Entry Ball Valve

Side Entry Ball Valve Specification

- Pressure

- Class 150 / 300 / 600 / 900

- Connection

- Flanged, Screwed, Welded

- Structure

- Side Entry, Two-piece or Three-piece

- Channels

- Single or Double Channel

- Caliber

- Full Bore / Reduced Bore

- Material

- Forged or Cast Carbon Steel / Stainless Steel

- Power

- Manual, Electric, Pneumatic

- Media

- Oil, Gas, Water, Chemical

- Temperature of Media

- -29C to 200C

- Port Size

- inch to 8 inch

- Flange

- ANSI, DIN, JIS Standard

- Finish

- Corrosion Resistant Painted / Polished

- Application

- Petrochemical, Power Plants, Water Treatment, Oil & Gas

- Handle Type

- Lever or Gear Operated

- Seating Material

- PTFE / Metal Seated

- Ball Type

- Float / Trunnion Mounted

- Leakage Class

- ISO 5208 Rate A / API 598

- End Connection

- RF / RTJ / BW / SW

- Fire Safe Design

- Yes (API 607 / API 6FA)

- Body Material Grade

- ASTM A216 WCB / A351 CF8M

- Operation

- Quarter Turn

- Stem Design

- Anti Blow-Out

- Anti-Static Device

- Provided

- Maintenance

- Low Maintenance Design

- Testing Standard

- API 598

- Face to Face Dimension

- As per ASME B16.10

- Locking Device

- Optional

- Actuator Mounting Pad

- ISO 5211

- Flow Direction

- Bi-Directional

Side Entry Ball Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About Side Entry Ball Valve

Side Entry Ball Valve

Size | 2" to 56" (50 mm to 1400 mm) |

ASME Class | Class 150 to 2500 |

Design Standard | API 6D |

Trunnion-mounted Ball Valve design complies to API 6D

Wide portfolio of Side-entry and Top-entry designs

Fugitive emissions

Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH

Fire safe design - to API 607 and API 6FACE Marking

Meets requirements of Pressure Equipment Directive 2014/68/EU,

Pneumatic shell test conducted at 1.1 times rated pressure to check shell integrity, when required Double block and bleed (DBB) feature

Valves are designed and tested for automatic cavity relief

Anti-blowout stem design

Coil springs used for consistent seat loading and lower operating torque

Lip seals provided for low temperature services

Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

Wide portfolio of Side-entry and Top-entry designs

Options: Buried service, Cryogenic

Offered with Electric, Pneumatic and Hydraulic Actuators

In-house Tests Capabilities

Versatile Flow Control for Industrial Needs

The Side Entry Ball Valve's bi-directional flow capability, available in full bore or reduced bore, fits seamlessly into petrochemical, power plant, water treatment, and oil & gas setups. These valves meet stringent leakage and fire safety standards, and their anti-static device further ensures safe operation across volatile media environments.

Low Maintenance and High Reliability Design

Built with forged or cast carbon steel or stainless steel, the valve's low maintenance design reduces downtime and operational costs. The anti blow-out stem and optional locking device provide enhanced safety and security, making it an ideal choice for mission-critical infrastructure.

FAQ's of Side Entry Ball Valve:

Q: How is the Side Entry Ball Valve operated and what actuator options are available?

A: The valve operates with a simple quarter-turn mechanism and can be controlled manually (lever or gear operated), or automatically via electric or pneumatic actuators mounted on ISO 5211 pads.Q: What is the process for installing the Side Entry Ball Valve in my system?

A: Installation follows the ASME B16.10 face-to-face dimension standard, with end connections available in RF, RTJ, BW, or SW types. Always follow manufacturer guidelines to ensure proper alignment and tight sealing, depending on system pressure and media.Q: Where can the Side Entry Ball Valve be applied effectively?

A: It is suitable for a wide range of industries including petrochemical, water treatment, power plants, and oil & gas sectors due to its compatibility with various media-oil, gas, water, and chemicals-and temperature resistance from -29C to 200C.Q: What benefit does the fire-safe design provide in industrial applications?

A: Certified to API 607 and API 6FA, the fire-safe design ensures that the valve maintains shutoff integrity during fire incidents, providing crucial protection for personnel and equipment in hazardous environments.Q: When is a float ball type recommended over a trunnion-mounted ball type?

A: Float type is ideal for low pressure and smaller valves, while trunnion-mounted ball design is recommended for high pressure and larger sizes, offering lower operating torque and enhanced sealing under high pressure conditions.Q: What maintenance is required for this valve and how often should it be performed?

A: The valve features a low maintenance design; periodic inspection of seat integrity and actuator performance is recommended based on operating conditions. Its robust build minimizes routine servicing, often aligning with planned plant maintenance cycles.Q: Why is an anti-static device important in ball valves for oil, gas, and chemical services?

A: Anti-static devices prevent the accumulation of electrostatic charge between the ball and stem, reducing the risk of sparks that might ignite flammable media. This provides additional safety in volatile applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Three Way Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Temperature of Media : 20C to 180C

Power : Manual

Structure : Other, Three Way

Finish : Polished

Single Piece Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Temperature of Media : Up to 180C

Power : Manual

Structure : Other, Single Piece

Finish : Polished

Pneumatic Actuator Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Temperature of Media : 20C to 180C

Power : Pneumatic

Structure : Other, Ball Valve

Finish : Polished / Painted

Electric Motorized Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Temperature of Media : 10C to 80C

Power : 220V AC

Structure : Other, Ball Valve

Finish : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese