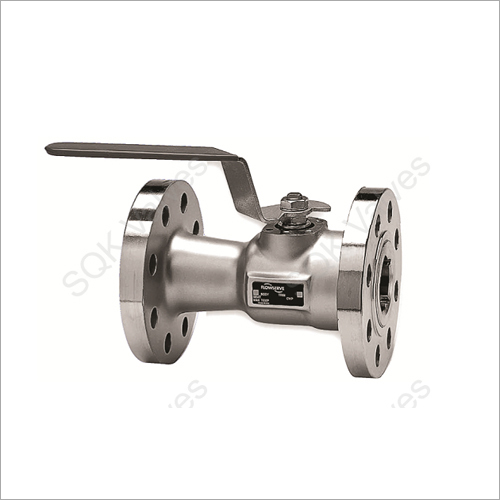

Single Piece Ball Valve

Single Piece Ball Valve Specification

- Pressure

- Up to 25 Bar

- Connection

- Screwed, Socket Weld, Flanged

- Caliber

- Full Bore

- Channels

- 2 Way

- Structure

- Single Piece

- Material

- Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas

- Temperature of Media

- Up to 180C

- Port Size

- 15mm to 100mm

- Flange

- ASME/ANSI B16.5

- Finish

- Polished

- Application

- Industrial, Chemical, Petrochemical, Water Treatment

- Operation

- Quarter Turn

- Handle Material

- Stainless Steel with PVC Sleeve

- Working Life

- 50,000 Cycles

- End Connection

- Threaded/Flanged

- Seat Material

- PTFE

- Mounting

- ISO 5211 Pad

- Size Range

- 1/2" to 4"

- Body Material Specifications

- CF8/CF8M/SS304/SS316

- Testing Standard

- API 598

- Leakage Class

- Class VI

- Body Design

- Blowout Proof Stem

Single Piece Ball Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About Single Piece Ball Valve

Single Piece Ball Valve

Size | 2" to 56" (50 mm to 1400 mm) |

ASME Class | Class 150 to 2500 |

Design Standard | API 6D |

Trunnion-mounted Ball Valve design complies to API 6D

Wide portfolio of Side-entry and Top-entry designs

Fugitive emissions

Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH

Fire safe design - to API 607 and API 6FACE Marking

Meets requirements of Pressure Equipment Directive 2014/68/EU,

Pneumatic shell test conducted at 1.1 times rated pressure to check shell integrity, when required Double block and bleed (DBB) feature

Valves are designed and tested for automatic cavity relief

Anti-blowout stem design

Coil springs used for consistent seat loading and lower operating torque

Lip seals provided for low temperature services

Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

Wide portfolio of Side-entry and Top-entry designs

Options: Buried service, Cryogenic

Offered with Electric, Pneumatic and Hydraulic Actuators

In-house Tests Capabilities

Durable Blowout-Proof Design

The single piece ball valve is engineered with a blowout-proof stem, maximizing operator safety and minimizing risk under rigorous working conditions. This design enhances reliability, especially in high-pressure environments up to 25 Bar, providing confidence in critical industrial applications.

Versatile Connection Options

Available in threaded, socket weld, and flanged end connections, the valve integrates seamlessly with piping systems across industries. Manufactured to ASME/ANSI B16.5, it accommodates installation flexibility, supporting various project requirements for water, oil, and gas media.

Long-term Performance and Reliability

Tested to API 598 standard and built for a lifespan of up to 50,000 cycles, this valve delivers consistent operational excellence in chemical, petrochemical, and water treatment sectors. The PTFE seat ensures superior sealing, while the polished stainless steel body resists corrosion for prolonged service.

FAQ's of Single Piece Ball Valve:

Q: How does the blowout-proof stem design enhance safety in this ball valve?

A: The blowout-proof stem prevents accidental ejection of the stem under high pressure, ensuring safer operation for personnel and reducing the risk of failure during service. This design is especially beneficial in demanding industrial environments.Q: What is the recommended process for installing this ball valve to ensure optimal performance?

A: Install the valve using appropriate end connections (threaded, socket weld, or flanged) according to pipeline specifications, and verify compatibility with ASME/ANSI B16.5 standards. Ensure that the ISO 5211 pad is properly aligned if mounting actuators. Conduct a leak test as per API 598 after installation.Q: When should the ball valve be chosen for an application involving high pressure or corrosive media?

A: The single piece ball valve made from CF8/CF8M/SS304/SS316 stainless steel is suitable for high-pressure (up to 25 Bar) and corrosive media applications due to its robust construction and PTFE seat, which resists chemical degradation and ensures reliable sealing.Q: Where can this valve be utilized within industrial settings?

A: It is used in industrial, chemical, petrochemical plants, and water treatment facilities, especially where full bore flow, tight shut-off, reliable manual control, and versatile installation options are required.Q: What benefits does the PTFE seat provide over other seat materials?

A: PTFE seats deliver excellent chemical resistance, minimal friction, and superior sealing, resulting in low leakage (Class VI), reduced maintenance, and prolonged valve life even in harsh working conditions.Q: How can users ensure long service life and reliable operation of this ball valve?

A: Regularly inspect the valve for signs of wear, operate within recommended pressure and temperature limits, and maintain cleanliness of the handling mechanism and media flow path. Scheduled maintenance and adherence to API 598 test procedures help ensure optimal performance over 50,000 operation cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Four Way Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Media : Other, Water, Oil, Gas, Steam, Chemical

Structure : Other, Four Way Ball, Floating Ball Type

Channels : Fourway (L, T, X Port)

Flange : ANSI B16.5, DIN, JIS Standard

Three Piece Ball valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Media : Other, Water, Gas, Oil, Air, Chemical

Structure : Other, Three Piece

Channels : 2 (twoway)

Flange : Optional

T Port Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Media : Other, Water / Oil / Gas

Structure : Other, Three Way T Port

Channels : T Type

Flange : ANSI / DIN / JIS Standard

Gear Operated Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Media : Other, Water, Oil, Gas, Steam

Structure : Other, Floating Ball / Trunnion Mounted

Channels : 2Way

Flange : ANSI B16.5 / DIN Std

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese