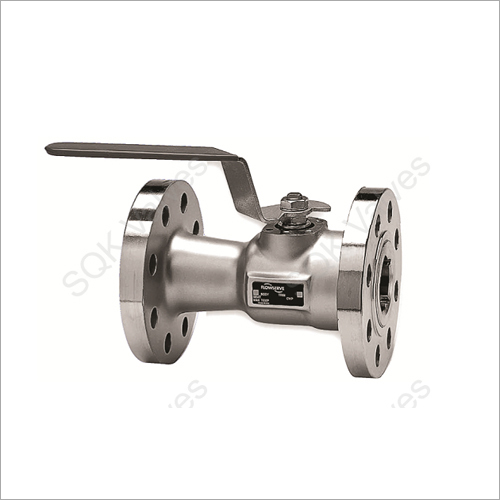

Gear Operated Ball Valve

Gear Operated Ball Valve Specification

- Connection

- Flanged

- Pressure

- PN16, PN25, Class 150 to 300

- Caliber

- Full Bore / Reduced Bore

- Channels

- 2-Way

- Structure

- Floating Ball / Trunnion Mounted

- Material

- Cast Iron / Cast Steel / Stainless Steel

- Power

- Manual Gear Operated

- Media

- Water, Oil, Gas, Steam

- Temperature of Media

- -20C to 200C

- Port Size

- 2 to 24

- Flange

- ANSI B16.5 / DIN Std

- Finish

- Epoxy Coated / Painted / Natural

- Application

- Industrial / Chemical / Oil & Gas / Water Treatment

- Size Range

- DN50 to DN600

- Seat Material

- PTFE / RPTFE / Metal Seated

- Fire Safe Design

- Available as per API 607

- Body Material Grade

- WCB / CF8 / CF8M

- Operation Type

- Quarter Turn

- Torque Requirement

- As per Valve Size & Application

- Design Standard

- API 6D / ISO 17292

- Face to Face Dimension

- ANSI B16.10

- End Connection

- Wafer / Lug / Butt Weld on request

- Actuator Mounting Pad

- ISO 5211

- Leakage Test

- 100% Tested as per API 598

Gear Operated Ball Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About Gear Operated Ball Valve

SQK Gear Operated Ball Valve

Size | 2" to 56" (50 mm to 1400 mm) |

ASME Class | Class 150 to 2500 |

Design Standard | API 6D |

Trunnion-mounted Ball Valve design complies to API 6D

Wide portfolio of Side-entry and Top-entry designs

Fugitive emissions

Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH

Fire safe design - to API 607 and API 6FACE Marking

Meets requirements of Pressure Equipment Directive 2014/68/EU,

Pneumatic shell test conducted at 1.1 times rated pressure to check shell integrity, when required Double block and bleed (DBB) feature

Valves are designed and tested for automatic cavity relief

Anti-blowout stem design

Coil springs used for consistent seat loading and lower operating torque

Lip seals provided for low temperature services

Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

Wide portfolio of Side-entry and Top-entry designs

Options: Buried service, Cryogenic

Offered with Electric, Pneumatic and Hydraulic Actuators

In-house Tests Capabilities

Precision Engineering and Build Quality

Crafted with premium grades such as WCB, CF8, and CF8M, these ball valves are suitable for demanding environments. The body and seat materials provide excellent corrosion resistance and withstand various media, including water, oil, gas, and steam, at temperatures from -20C to 200C.

Operational Versatility and Safety Features

Each valve operates on a reliable manual gear system requiring torque adjusted per application and valve size. Fire-safe designs comply with API 607, while 100% leakage testing using API 598 standards ensures safety and reliability in critical processes.

Customizable Connections and Sizes

Versatile end connections (wafer, lug, butt weld) and a broad size range (DN50 to DN600) enable integration across pipelines and systems. With flange standards (ANSI B16.5 / DIN) and finishes (epoxy, painted, natural), our valves suit diverse operational and aesthetic requirements.

FAQ's of Gear Operated Ball Valve:

Q: How is a gear operated ball valve used in industrial settings?

A: Gear operated ball valves are commonly used to control and isolate the flow of media such as water, oil, gas, and steam within industrial pipelines. The manual gear system allows precise operation and secure sealing, making them ideal for applications requiring reliable shut-off and regulation.Q: What are the benefits of choosing WCB, CF8, or CF8M body materials for these valves?

A: Selecting WCB, CF8, or CF8M grades ensures resistance to corrosion, high strength, and compatibility with various process fluids. These materials provide longevity and robust performance in harsh conditions, enhancing valve life and process safety.Q: When should fire-safe designed ball valves per API 607 be implemented?

A: Fire-safe ball valves should be used in facilities where there is a risk of fire or exposure to flammable materials. Compliance with API 607 guarantees that the valve maintains tight shut-off and performance even under fire conditions, protecting assets and personnel.Q: Where can these ball valves be installed regarding connection types?

A: These valves offer flexible installation with wafer, lug, butt weld, and flanged end connections compatible with ANSI B16.5 or DIN standards. This adaptability makes them suitable for numerous pipeline configurations in industrial, chemical, and oil & gas facilities.Q: What is the leakage testing process for these valves?

A: Each valve undergoes rigorous leakage testing in accordance with API 598 standards. This process verifies the integrity of the seat and body, ensuring zero leakage and reliable operation under specified pressure ranges (PN16, PN25, Class 150 to 300).Q: How is the required operating torque determined for these ball valves?

A: The operating torque is calculated based on valve size, bore type, pressure rating, and the specific application's media characteristics. This ensures smooth manual operation without compromising sealing performance, and can be tailored as per customer request.Q: What advantages are achieved with the valve's actuator mounting pad complying with ISO 5211?

A: An ISO 5211 actuator mounting pad allows for easy and standardized attachment of actuators, enabling future upgrades from manual to automated operation. This feature provides end-users with flexibility and efficiency in both installation and maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves Category

Single Piece Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Caliber : Full Bore

Finish : Polished

Material : Stainless Steel

Channels : 2 Way

Top Entry Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Caliber : Full Bore / Reduced Bore

Finish : Anticorrosive Coated

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Channels : Single Channel

Pneumatic Actuator Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Caliber : Full Bore

Finish : Polished / Painted

Material : Other, Stainless Steel / Carbon Steel

Channels : 2 Way

L Port Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Caliber : Standard

Finish : Polished

Material : Other, Stainless Steel / Cast Iron / Brass

Channels : L Port

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese