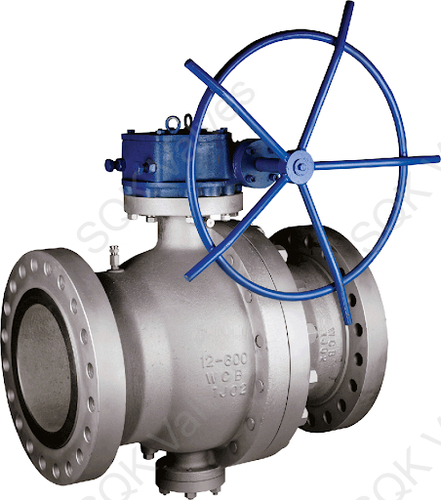

SQK A351 CF3 Cast Stainless Steel Ball Valve

SQK A351 CF3 Cast Stainless Steel Ball Valve Specification

- Structure

- One Piece

- Pressure

- PN16

- Channels

- Two Way

- Connection

- Flanged

- Caliber

- 50 mm

- Material

- A351 CF3 Cast Stainless Steel

- Power

- Manual

- Media

- Water, Oil, Gas

- Temperature of Media

- -20C to 180C

- Port Size

- 2 Inch

- Flange

- ANSI B16.5

- Finish

- Polished

- Application

- Industrial, Chemical Processing, Water Treatment

- Seal Material

- PTFE

- Seat Material

- PTFE

- End Connection

- Flanged

- Mounting Pad

- ISO 5211

- Handle Type

- Lever

- Design Standard

- ASME B16.34

- Body Material

- Cast Stainless Steel CF3

- Leakage Class

- Class VI

- Surface Treatment

- Anti-corrosive

- Valve Type

- Full Bore Ball Valve

- Testing Standard

- API 598

- Operation Mode

- Quarter Turn

- Stem Material

- AISI 304 Stainless Steel

SQK A351 CF3 Cast Stainless Steel Ball Valve Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 7 Days

About SQK A351 CF3 Cast Stainless Steel Ball Valve

SQK A351 CF3 Cast Stainless Steel Ball Valve

Size | 2" to 56" (50 mm to 1400 mm) |

ASME Class | Class 150 to 2500 |

Design Standard | API 6D |

Main Feature

· Trunnion-mounted Ball Valve design complies to API 6D

· Wide portfolio of Side-entry and Top-entry designs

· Fugitive emissions

· Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH

· Fire safe design - to API 607 and API 6FACE Marking

· Meets requirements of Pressure Equipment Directive 2014/68/EU,

· Pneumatic shell test conducted at 1.1 times rated pressure to check shell integrity, when required · Double block and bleed (DBB) feature

· Valves are designed and tested for automatic cavity relief

· Anti-blowout stem design

· Coil springs used for consistent seat loading and lower operating torque

· Lip seals provided for low temperature services

· Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

· Wide portfolio of Side-entry and Top-entry designs

· Options: Buried service, Cryogenic

· Offered with Electric, Pneumatic and Hydraulic Actuators

· In-house Tests Capabilities

Reliable Full Bore Performance

The SQK A351 CF3 Ball Valve provides unobstructed flow and minimal pressure loss due to its full bore structure. Ideal for various industrial sectors, including water treatment and chemical processing, the valve's robust construction guarantees lasting performance, even in demanding operating conditions.

Precise Shutoff and Durability

Equipped with PTFE seats and seals, this ball valve delivers tight shutoff (Class VI leakage) and superior chemical resistance. The cast stainless steel CF3 body, combined with a polished anti-corrosive finish, ensures durability and protection against harsh media.

Safe and Easy Operation

Designed for manual use, the quarter-turn lever handle facilitates straightforward operation. The valve's standardized mounting pad (ISO 5211) enables flexibility if actuation is needed, accommodating future automation upgrades for enhanced operational safety and efficiency.

FAQ's of SQK A351 CF3 Cast Stainless Steel Ball Valve:

Q: How is the SQK A351 CF3 Cast Stainless Steel Ball Valve operated in industrial settings?

A: This ball valve utilizes a manual lever, allowing for quick quarter-turn operation to open or close the flow. The ISO 5211 mounting pad also supports actuator installation for automated control if required.Q: What media types are suitable for use with this full bore ball valve?

A: The valve is compatible with water, oil, and gas, handling these media safely within a temperature range of -20C to 180C, thanks to its PTFE seats and corrosion-resistant CF3 stainless steel construction.Q: Where is the SQK A351 CF3 Ball Valve typically installed?

A: This valve finds application in industrial facilities, chemical processing plants, and water treatment systems. Its flanged ends (ANSI B16.5) ensure secure connections to standard piping in such environments.Q: What testing standards does this valve meet during quality assurance?

A: It is tested in accordance with API 598, ensuring tight shutoff and leak-free operation. The design follows strict ASME B16.34 specifications for safety and performance.Q: What benefits does the PTFE sealing provide for this valve?

A: PTFE seats and seals offer excellent chemical resistance and low friction, ensuring long-lasting performance, minimal maintenance, and reliable leak-tightness even with aggressive or fluctuating media.Q: How does the valve's anti-corrosive finish contribute to longevity?

A: The polished, anti-corrosive surface treatment protects the stainless steel body against environmental degradation, maintaining the valve's integrity and enhancing durability in harsh operating conditions.Q: When should this ball valve be chosen over other types for process applications?

A: Select this full bore ball valve when you need minimal pressure drop, high durability, and secure shutoff for fluid control in demanding industrial, water treatment, and chemical processing systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valves By Material Category

SQK A352 LCB Carbon Steel Ball Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Connection : Flanged

Temperature of Media : 46C to +345C

Channels : Single Channel

Port Size : 2 Inch

SQK A216 WCC Cast Carbon Steel Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Connection : Flange

Temperature of Media : 29C to +425C

Channels : Single

Port Size : 2 Inch

SQK A350 LF2 Alloy Steel Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Connection : Flanged End

Temperature of Media : 46C to +200C

Channels : Twoway

Port Size : 1/2 inch to 12 inch

SQK A217 C5 Cast Alloy Steel Ball Valve

Price Range 5000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 5 Units

Connection : Flanged

Temperature of Media : Up to 600C

Channels : 2 Way

Port Size : 2 Inch (50 mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese